CIRCUSOL: Solar power business models towards a circular economy in Europe (PRESS RELEASE)

CIRCUSOL: Solar power business models towards a circular economy in…

Photovoltaic (PV) waste, associated with the exponentially growing PV installations on a global scale, presents today an emerging environmental challenge but also brings unprecedented and multifold value creation opportunities.

In this context, significant PV business and research and development (R&D) efforts shift towards establishing a more sustainable, environmentally friendly and economically viable end‐of‐life (EoL) management for PV modules: including recycling, recovery of raw materials, repair/refurbishment and even re‐use of decommissioned or failed PV modules. In the CIRCUSOL project, PV partners aspire to formalize the repair/refurbish and re‐use value chains in the PV industry and propose a circular business model, based on a product‐service system (PSS). The topics and the relevant reported literature are examined from both circular economy and technology perspective. The review indicates considerable technological and operational know‐how in PV EoL management that already exists and continuously evolves in mature PV markets. On the other hand, R&D in repair/refurbishment of decommissioned and/or failed PV modules remains scarce, and best practices and commercial services for reliability testing/re‐certification and trading of second‐life PV modules are neither standardized nor consolidated into any PSS or business model.

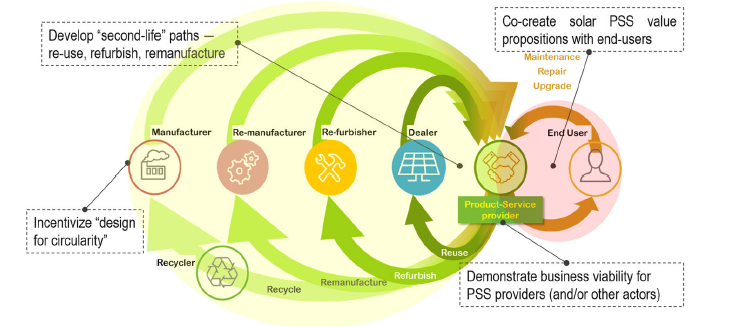

CIRCUSOL aspires to formalize the recycling, repair/refurbish and re‐use segment in the PV value chains and to propose adapted technical standards/regularity framework for these emerging EoL business pathways for PV. This will be the foundation to develop and validate a product‐service system (PSS) in the PV sector (next to the batteries sector, which is also addressed in CIRCUSOL), to enable the implementation of circular business models. The proposed PSS based circular business model and its underlying value‐creation goals throughout PV EoL are depicted in Figure 1. As such, PV modules can be designed for both recyclability and circularity towards second‐life paths, i.e. for re‐use, re‐manufacturing and/or refurbishment. Moreover, in this way, decision making for the optimal life path for each PV module can be consolidated and carried out by product service providers, who are also responsible for co‐creating value propositions to the PV end‐users.

CIRCUSOL aspires to formalize the recycling, repair/refurbish and re‐use segment in the PV value chains and to propose adapted technical standards/regularity framework for these emerging EoL business pathways for PV. This will be the foundation to develop and validate a product‐service system (PSS) in the PV sector (next to the batteries sector, which is also addressed in CIRCUSOL), to enable the implementation of circular business models. The proposed PSS based circular business model and its underlying value‐creation goals throughout PV EoL are depicted in Figure 1. As such, PV modules can be designed for both recyclability and circularity towards second‐life paths, i.e. for re‐use, re‐manufacturing and/or refurbishment. Moreover, in this way, decision making for the optimal life path for each PV module can be consolidated and carried out by product service providers, who are also responsible for co‐creating value propositions to the PV end‐users.

To access the full study, click here.

Reference: Tsanakas JA, van der Heide A, Radavičius T, et al. Towards a circular supply chain for PV modules: Review of today's challenges in PV recycling, refurbishment and re‐certification. Prog Photovolt Res Appl. 2019;1–11. https://doi.org/10.1002/pip.3193

CIRCUSOL: Solar power business models towards a circular economy in…