CIRCUSOL: Solar power business models towards a circular economy in Europe (PRESS RELEASE)

CIRCUSOL: Solar power business models towards a circular economy in…

Lifetime extension of products, components and materials, realized via re-use and repair is one of the cornerstones of a circular economy. Over recent years there has been an ever-growing deployment of PV, leading to an expected increase in revamping/repowering of installations in the future. This means many PV panels will be decommissioned before reaching the end of their technical lifetime. One of the CIRCUSOL aims is to extend the use life of PV installations by developing 2nd life deployment pathways.

Within CIRCUSOL it was assessed whether and under which conditions it is worthwhile to extend the use life of PV from both the environmental and financial perspective. The environmental benefit of lifetime extension is not as obvious as one might expect. It is important to take into account the ever-increasing efficiency of new PV in terms of electricity generation and the impact of possible transport when the solar panels are reused at a different location [1]. Nonetheless, the good news is: there is indeed an environmentally friendly business case for the lifetime extension.

It might seem obvious, but the PV deployed for 2nd life needs to be in good condition. Within CIRCUSOL it was assessed whether PV panels that require repair are eligible for use life extension. To a certain extent, the answer is positive. As long as it concerns limited interventions such as replacing cables or the junction box, it is financially viable to carry out these repairs. The impact of complex repairs was not fully examined, as current panels are not designed to be dismantled and repaired. Fortunately, increased repairability of PV is gaining importance. One of the CIRCUSOL partners is working on the design of more repairable PV panels.

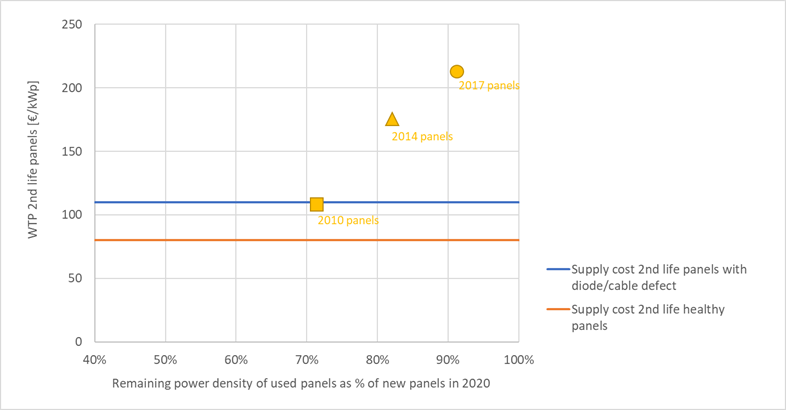

Besides the good condition of PV panels, it is key that they still generate sufficient electricity (sufficient remaining power density). This not only because of the efficiency of PV diminishes over time, but mainly due to the ever-increasing efficiency of new PV. The financial analysis showed that it is economically feasible to redeploy panels up to 12 years old. From the environmental perspective, even for older panels use life extension is preferred over opting for new panels.

A final parameter that determines the feasibility of the 2nd life deployment of PV is the cost of the rehabilitation process as the panels need to be tested and recertified. Improved insight into the PV panel rehabilitation process and its related costs are required, the CIRCUSOL team is investigating this.

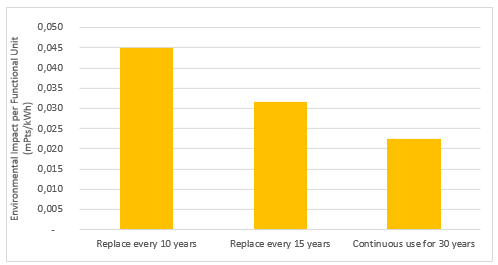

Environmental impact per functional unit (per kWh electricity produced) for three scenarios’ applying different panel service lifetime, over a 30-year period. In the first situation ‘Replace every 10 years’ panels (and inverter) are replaced every 10 years with new, more efficient panels. In the second situation ‘Replace every 15 years’, panels (and inverter) are replaced after 15 years with new more efficient ones. In the ‘Continuous use scenario’, panels are kept in use for 30 years (one inverter replacement takes place in year 15). Environmental impact is expressed as a single score (mPts), covering 16 different environmental impact categories (Product Environmental Footprint method).

The willingness to pay (WTP) for 2nd life panels, expressed in €/kWp heavily depends on the remaining power density and lifetime of the panels. Taking into account a technical lifetime of 30 years the remaining lifetimes of panels from 2010, 2014 and 2017 are - respectively - 20, 24 and 27 years. Obviously, the remaining power density for more recent panels is higher as well, leading to an increased WTP which well offsets the costs incurred on the supply side.

[1] For this analysis, the reuse is considered to take place in the same geographical region, where a similar irradiation rate applies.

Author:

Anse Smeets, Circular Economy Researcher at VITO

Co-authors:

Neethi Rajagopalan, R&D Analyst, Sustainable Built Environment at VITO

Karolien Peeters, Researcher Built Environment & Smart Cities at VITO

CIRCUSOL: Solar power business models towards a circular economy in…